Catalogue

Loading Arm

Design, standard and engineering

Design & standard

Main Forged FFD’s design principles:

- Lean technology

- Easy and safe to operate

- Low maintenance

- Environment protection

- Easy to ship and erect on site

Full compliance with the international standards:

- ASME

- PED 97/ 23/CE (Pressure Equipment Directive)

- ATEX Directive 94/9/EC

- OCIMF (Oil Companies International Marine Forum)

- EN/ISO

Engineering

Forged FFD follows all stages of MLA supply for the transfer ship-to-shore and shore-to-ship of LNG,

Hydrocarbons and Chemicals:

- Design of the structure, joints, kinematic mechanism, safety devices etc

- Structural Pier and connected piping verification and design

- Firefighting prevention and protection system design and verification

- Construction of the loading arms components and a relative assembly in the workshop

- Hydraulic test and Factory Acceptance Test

- Pier Installation

- Site Acceptance Test and assistance

- Mooring point, dolphin, hook up design and verification

Forged FFD also offers engineering services an industrial Project:

- Feasibility Study Estimated Costs

- Process Study

- Operating manual execution

- Basic engineering Design

- Front and Engineering Design (FEED)

Main structure

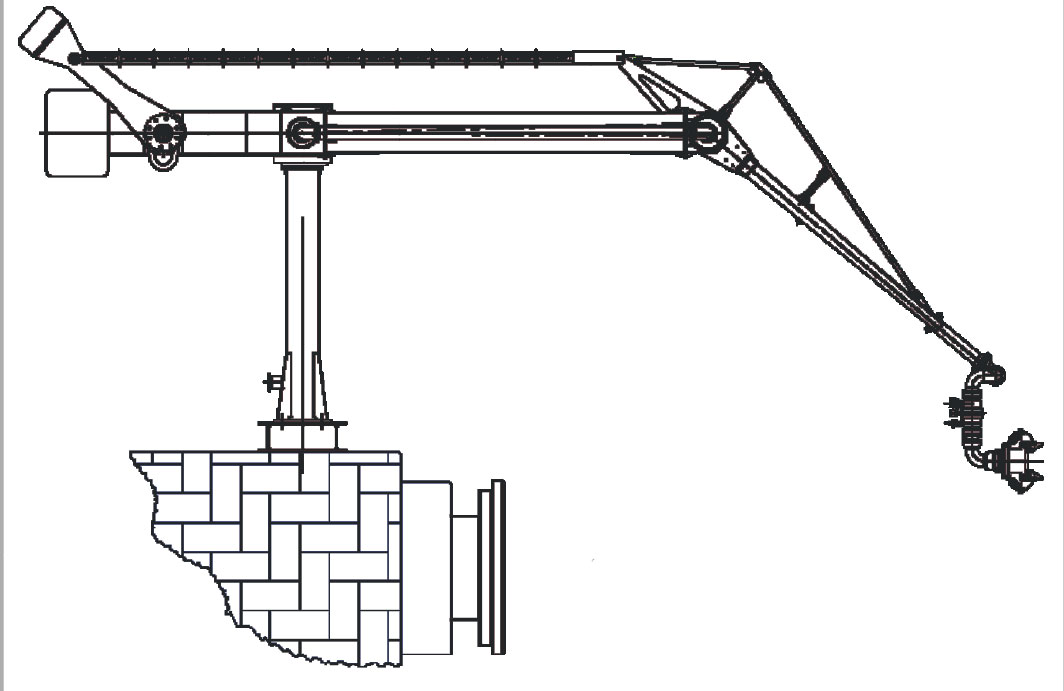

The Riser is fixed to the jetty and is connected to the terminal piping system.

At the upper of the riser is secured a cubic structure supporting the inboard arm. Two bearings, two swivel joints concentric to the bearings and a 90° elbow flanged to the joints are installed inside of this cubic structure. Disassembling of just only the 90° elbow gives you a possibility to substitute joints and gaskets immediately.

Even without the 90° elbow and joints during the maintenance operation, the marine loading arm can work in each position without any limitations and dangers.

Riser

The Outboard Arm has a tubular section which is equal to the nominal diameter of the Marine Loading Arm.

An auto-levelling system composed by triple swivel and flanged elbow is connected at the end section of the outboard arm, this system allows the best coupling of the manifold to the vessel.

Outboard arm

It is built by a self-supported structure anchored to the cubic structure by a thrust bearing.

A connection bearing for the main part of outboard arm and its joint, complete with a 90° flanged elbow is placed at the front end of the inboard loading arm.

Excluding the 90° elbow there is the possibility to replace rapidly the joint and gaskets of the outboard arm.

During the maintenance operation even without the 90° elbow and joints, the marine loading arm can operate in every position without limits.

The thrust bearing and the joint allow to the outboard loading arm a vertical rotation to be controlled and counterbalanced by a pantograph system with double counterweights.

The back end of inboard loading arm is composed by a fixed counter weight support system.

If needed, the loading arm can be equipped with a hydraulic motor and by means of an endless screws the hydraulic motor can be regulated to assure balancing of the loading arm in full and empty conditions.

Inboard arm

TO CONTINUE THE CONSULTATION DOWNLOAD THE CATALOGUE:

Download the catalogue

View the other catalogues