Catalogue

Flanges

Introduction

Forged FFD is a manufacturer and distributor of flanges from size ¼” up to 120” with years of experience and has based its value on quality, reliability, and fast delivery. Our goal is to satisfy a wide range of clients while maintaining the highest internationally accepted standards.

Why choose Forged FFD?

Our elite staff and veteran machinists ensure the highest quality of care in every stage of machining and production. Our raw materials are sourced locally and are certified by external inspectors to guarantee the best Italian quality that our customers expect and deserve for all their oil, gas, water, and other industrial activities.

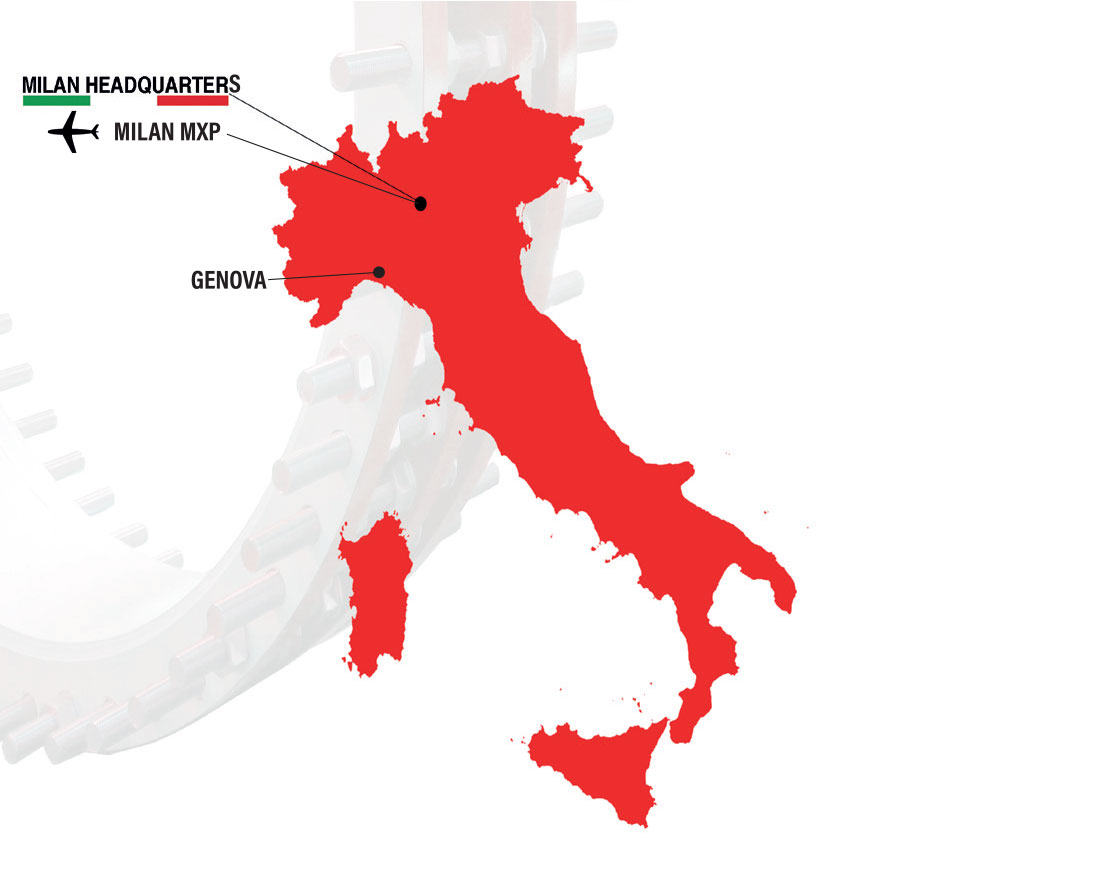

Our engineers have great experience in design and development and use the latest 2D and 3D CAD software which allows us to offer some of the most advanced and unique products available. With a strategic location just outside of Milan in the north of Italy, we have easy access to the Port of Genoa which is one of the largest in the Mediterranean Sea

FLANGES

A flange is a plate or ring that attaches to a pipe or valve with the purpose of providing extra support for strength, blocking off a pipeline, implementing a secure attachment of other items, and more. They are usually welded to or secured with studs and nuts and can be found at the end of various pipeline connections.

Our flanges can be customized to meet any specifications and are always manufactured according to international standards such as ANSI or ASME and many more. The most common ANSI/ASME pressure classes are 150#, 300#, 400#, 600#, 900#, 1500#, and 2500#.

Flanges are manufactured in a variety of materials including stainless steel, cast iron, aluminum, brass, bronze, plastic, and other specialized metals. The most commonly used material is forged carbon steel which we can provide with a machined surface.

The three main types are Welding Neck, Socket Welded, or Blind Flanges.

WELDING NECK FLANGES

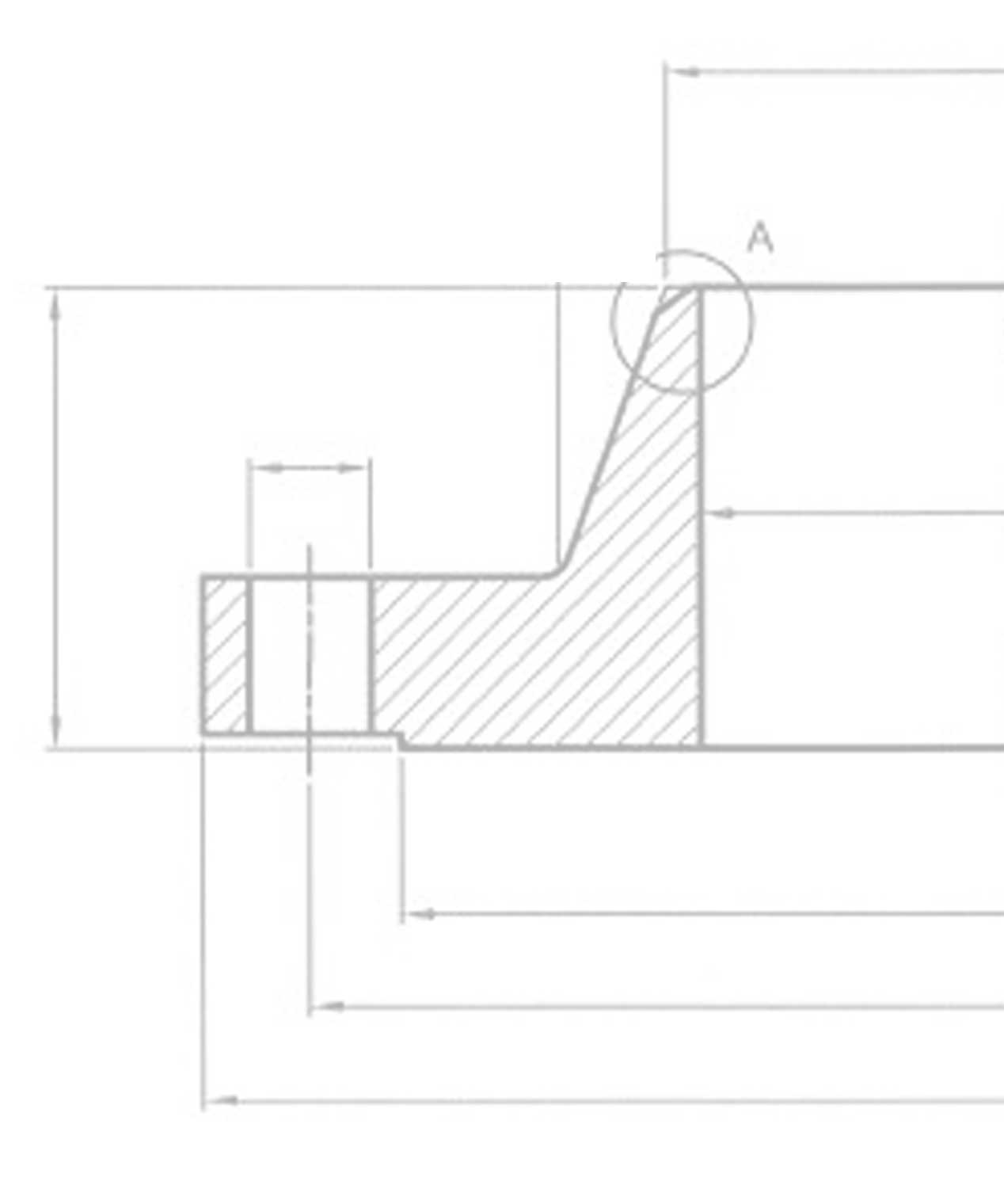

Welding Neck Flanges are easy to recognize because of their extended neck that provides important reinforcement. They are used in several applications including high pressure and sub-zero or elevated temperatures. They are commonly found when branching pipes from a tank or vessel. Welding neck flanges allow for a smooth transfer of stress between the flange and pipe.

“Long” welding neck flanges acts as an extension and is longer than the standard weld neck flange. This allows even easier access to a tank or vessel and sometimes replaces small sections of piping. Both types of welding necks allow for easy assembly and disassembly as needed for repair and maintenance.

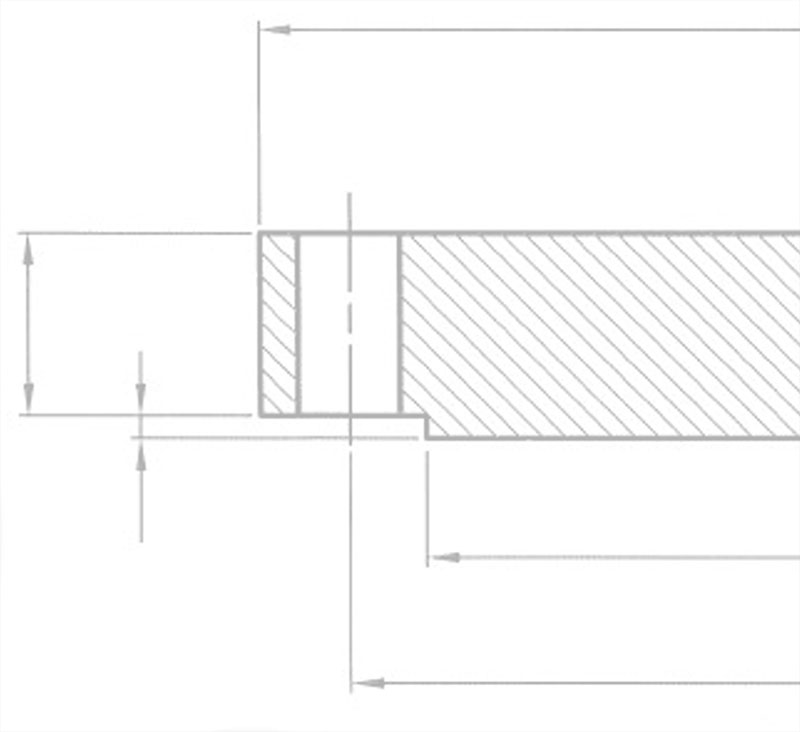

SOCKET WELD FLANGES

Socket weld flanges are popular for small-bore, high-pressure pipes, but can also be found in larger, low pressure piping systems as well. These flanges are attached by inserting the pipe into the socket end, providing stability, and then connected with a fillet weld around the top of the connection. This allows for a better flow of the fluid or gas in the pipe.

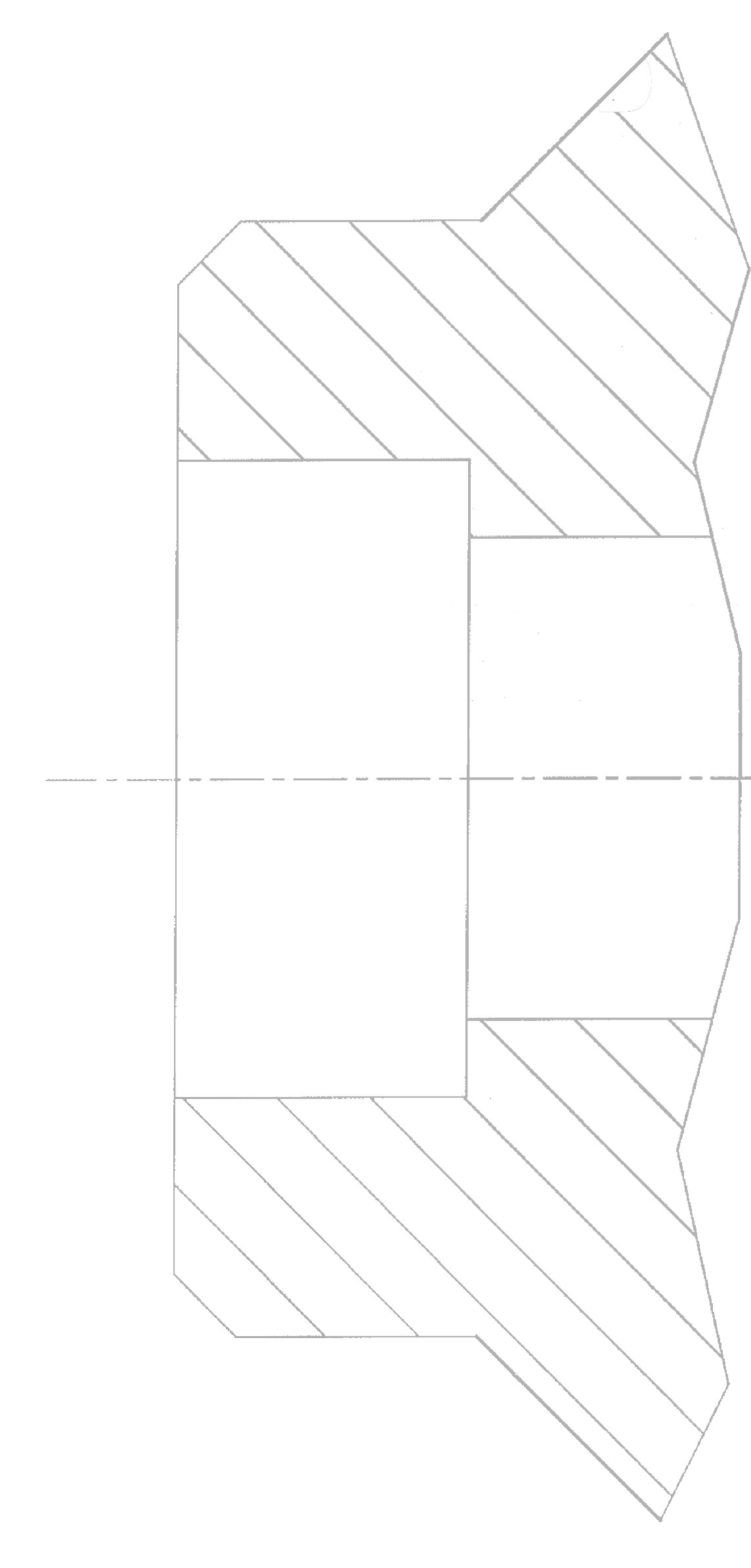

BLIND FLANGES

Blind Flanges are manufactured without a bore and are used to block off the ends of piping, valves, and other pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges are the most highly stressed of all. They are also used for pressure testing the flow through a pipe system. In addition, blind flanges allow for easy access into the piping system if there is any repairs or maintenance that needs to be done.

TO CONTINUE THE CONSULTATION DOWNLOAD THE CATALOGUE:

Download the catalogue

View the other catalogues